Pneumatics or Hydraulics?

You know you need a fluid power system, but how do you choose the right one? Let’s break down the pros and cons of the two primary fluid power systems: hydraulics and pneumatics.

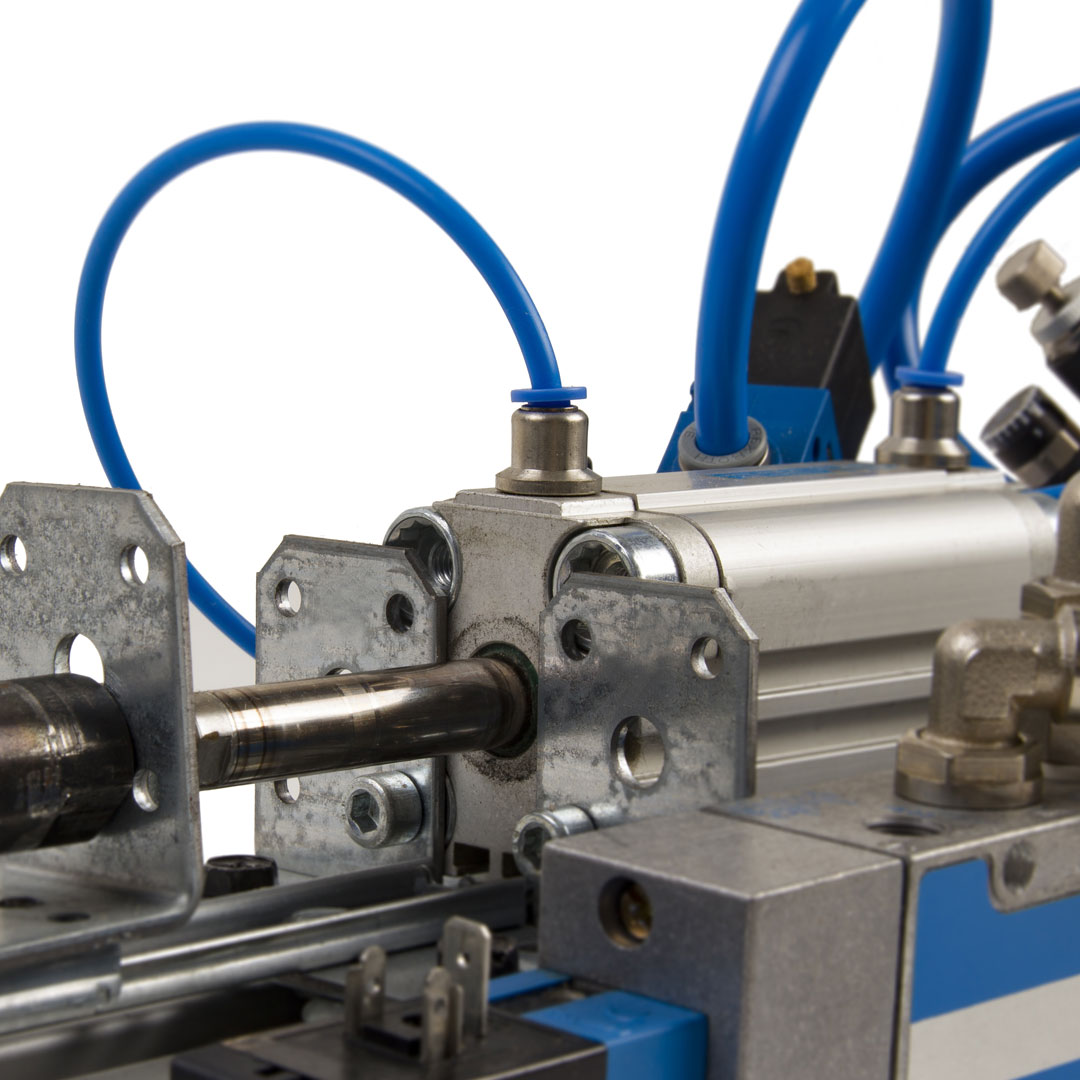

Pneumatics

Pneumatic fluid circuits use a gas to move power from one location to another. Because gases can be compressed and thusly require more space, pneumatic systems must operate at lower pressures. A typical pneumatic system operates at 100 pounds per square inch (PSI) or less. While the relatively low pressure does present as a limitation, it does allow pneumatic systems to be constructed from lighter-weight materials than their hydraulic counterparts.

Lighter materials and relatively fewer operating parts result in a lower initial cost for a pneumatic system. Depending on usage, operating costs may be higher due in part to the considerable power draw required to effectively and quickly compress the gas for use in power transmission. Pneumatic systems are inadvisable for use in industrial applications requiring very fine, precision positioning because gas rapidly expands when decompressed resulting in an expected variability in force transmitted. This property also inhibits pneumatic systems from being used in static load bearing.

One advantage is that systems may be more suitable in manufacturing settings requiring accuracy and a more gentle operating force. While operating, pneumatic systems are often much quieter because the gas compression system is typically installed separately from the pneumatic circuit and actuator. Another cost benefit to pneumatic systems is their relatively low cleaning and maintenance cost. Gas as a power medium means fewer industrial incidents and the relatively simple systems can be maintained without specialized labor skillsets.

Hydraulics

While pneumatic circuits use gas to move power around, hydraulic systems use liquids. Oil is the most common liquid medium. Hydraulic fluids are, for the most part, not compressible. And because they do not compress, hydraulics are capable of operating at much higher pressures, typically between 1,500 PSI and 2,500 PSI.

Hydraulic systems tend to be quite a bit more complex than pneumatics. Their complexity and the relative cost of the necessary materials used for installation means that hydraulic systems are more expensive to install. Unlike a pneumatic system, which requires gas to be compressed and decompressed as needed for power transmission, hydraulic fluid remains under pressure in the circuit at all times resulting in lower operating costs over the lifetime of the system. There are several key advantages offered by hydraulics. Because hydraulic liquids are non-compressible, they are suitable for industrial uses where high degrees of precision positioning are needed. There is minimal variability in the expected force provided through the actuator. These systems are also capable of holding static loads for extended periods.

The higher pressures of a hydraulic system allow for significantly more force to be transmitted over a smaller area with a smaller machine footprint. These systems produce more power in smaller spaces across a smaller surface area as a result. There are a number of key drawbacks with a hydraulics circuit system. Because oil is the primary medium of transmission, a system leak will be costly and profuse unless detected and dealt with immediately. Circuits with increasingly higher pressure requirements have an increased risk of fire potential as a result of the hydraulic liquid overheating. While machines operating within expected parameters should present few issues, safety precautions are a necessary step.

The complexity of hydraulic systems requires a specialized fluid power skillset to maintain and repair if necessary. Clients may not have personnel capable of conducting such work. Therefor, maintenance requirements could mean longer system downtime and increased costs if third party labor becomes necessary. When it comes to fluid power systems there is no one-size-fits-all. Each system, be it pneumatic or hydraulic, brings a unique set of advantages and disadvantages. If you have questions concerning your specific fluid power needs, please feel free to contact our sales representatives.